Spray foam insulation is a two-component system comprising polyurethane, formed by reacting polyols and isocyanates. Polyols act as the polymer backbone, while isocyanates act as cross-linking agents. During application, the components are mixed, and a chemical reaction called polymerization occurs. This generates a viscous liquid that rapidly expands upon contact with air, forming a cellular structure. The resulting polyurethane foam can be closed-cell or open-cell, each offering distinct properties. The foam’s cellular structure reduces heat transfer and creates an effective air barrier, enhancing insulation. Spray foam insulation formulations may vary, with additives and fire retardants incorporated to meet specific requirements. Since spray foam reduces heat transfer so well, it’s one of the most used types of insulations in the United States.

ELI5:

Spray foam insulation is a material that’s used to keep buildings warm by stopping heat from escaping or sneaking in through the walls and ceilings. It’s made up of two main things called polyols and isocyanates. Polyols are like the building blocks of the insulation. They’re the ones that give the foam its structure and strength. Isocyanates, on the other hand, act like a kind of glue. They’re the ones that hold the polyols together, making the foam tough and long-lasting.

When you spray this foam insulation, you mix those polyols and isocyanates. When they get mixed they have a chemical reaction called polymerization. It’s like they become thick and sticky. Then, when you spray this mixture onto a surface it reacts with the air and starts expanding rapdily. It creates very tiny bubbles that make the foam look like a sponge. and depending on how they make the foam, those bubbles can be open or closed.

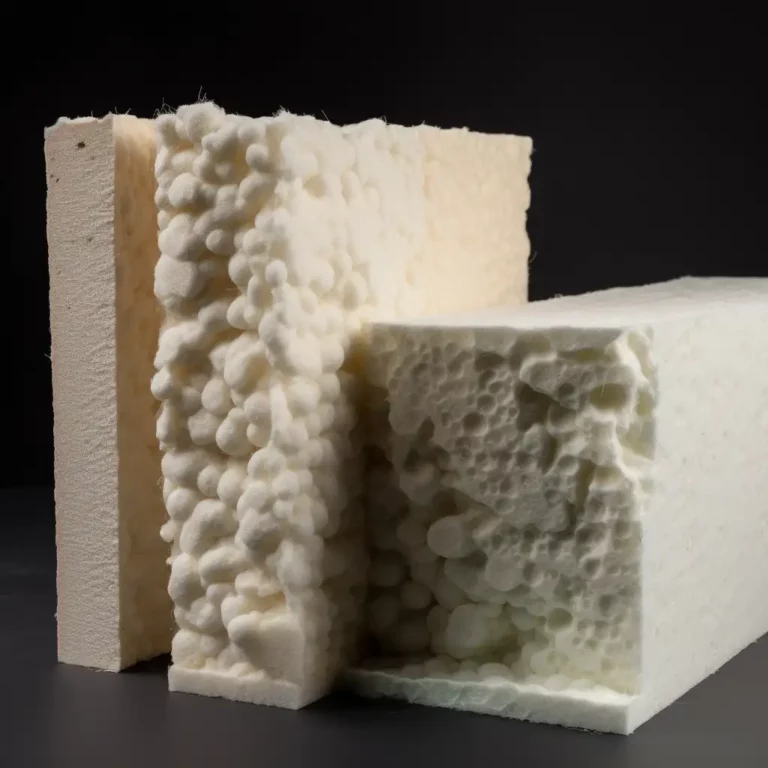

Closed-cell foam has extremely tiny bubbles packed really tight. They’re filled with gas, which makes the foam feel super dense and firm. And because of all that gas trapped in there, it’s great at keeping heat from getting through.

Open-cell foam is a bit different. Its bubbles are bigger, and they’re all connected to each other. That gives the foam a softer, more flexible feel. It still does a good job at insulating, but it allows some air and moisture to pass through.

Table of Contents

How Spray Foam Insulation Works

Spray foam insulation works by creating a continuous and seamless layer of insulation. When applied, the liquid foam expands and adheres to the surfaces, filling gaps, cracks, and voids. The expanding foam not only provides excellent thermal insulation but also acts as an effective air and moisture barrier.

The closed-cell structure of spray foam restricts the movement of air and minimizes convective heat transfer. This helps to maintain a consistent indoor temperature and reduces energy loss. Additionally, the foam’s ability to seal gaps and cracks prevents air infiltration, reducing drafts and improving overall energy efficiency.

Open Cell Foam

You’ll be amazed to know that open cell foam insulation can reduce your energy bills by up to 50%, providing an excellent option for insulating your home.

This type of insulation features a unique cellular structure, which allows air to flow through the tiny cells, giving it a sponge-like appearance and making it more flexible compared to its closed-cell counterpart.

While open cell foam may not offer the same level of moisture resistance as closed-cell foam, it boasts exceptional soundproofing benefits due to its ability to absorb and dissipate sound waves effectively.

Open-cell foam is primarily composed of polyurethane, which is formed through the reaction of polyols and isocyanates. During the reaction, blowing agents are incorporated to create gas bubbles within the foam structure. The resulting foam contains a network of interconnected cells, allowing air and moisture to penetrate the material. This composition results in a soft, flexible foam with a lower density.

Closed Cell Foam

Contrary to open cell foam, closed cell foam offers a higher level of moisture resistance and boasts impressive thermal insulation properties, making it an ideal choice for those seeking energy efficiency and durability in their home’s construction. As someone who cares about serving others, I’m excited to share the benefits of this insulation material with you:

- Moisture resistance: Closed cell foam provides a barrier against moisture infiltration, reducing the likelihood of mold growth and ensuring your home remains free from dampness-related issues.

- Environmental impact: Although closed cell foam is more dense than its open cell counterpart, it still has a relatively low global warming potential (GWP) compared to other insulating materials. This means that using closed cell foam can help reduce your home’s carbon footprint.

- Durability factors: The rigidity of closed cell foam makes it highly durable and long-lasting. Its strength allows it to perform well under pressure, such as in areas prone to flooding or high winds.

Closed-cell foam also consists of polyurethane, but with a higher density and a compact cellular structure. The cells are tightly packed and encapsulated, forming a barrier that restricts the movement of air and moisture. The high density is achieved by using different blowing agents that create smaller, more compact cells. Closed-cell foam exhibits a rigid and durable nature.

The distinct composition of open-cell and closed-cell foams gives them unique properties. Open-cell foam has a lower thermal conductivity and is more permeable to moisture vapor. It provides excellent sound-absorbing qualities and can conform to irregular surfaces. Closed-cell foam, with its higher density, offers higher compressive strength and improved moisture resistance. It provides a superior insulating barrier, blocking air and moisture infiltration more effectively. You might be asking yourself, do I need open cell foam or closed cell foam?

Expansion and Adhesion Properties

Spray foam insulation has amazing expansion and adhesion properties. These properties ensure a seamless, energy-efficient barrier that keeps your home cozy and draft-free. The expansion rate of spray foam is crucial in ensuring it fills all gaps, cracks, and crevices in the building envelope.

As the foam expands, its adhesion strength allows it to bond firmly to various surfaces such as wood, concrete, and metal. This strong bond helps create an air-tight seal that prevents air leakage and improves the overall thermal performance of your home. Additionally, the curing time of spray foam plays an essential role in achieving optimal performance by allowing for proper density and rigidity development.

Below is a table that highlights the surfaces open cell and closed cell foam will adhere too:

| Adhesion Material | Open-Cell Foam | Closed-Cell Foam |

|---|---|---|

| Wood | ✔️ | ✔️ |

| Metal | ✔️ | ✔️ |

| Concrete | ✔️ | ✔️ |

| Drywall | ✔️ | ✔️ |

| Plastics | ✔️ | ✔️ |

| Glass | ✔️ | ✔️ |

| Brick | ✔️ | ✔️ |

| Foam Board | ✔️ | ✔️ |

| Plywood | ✔️ | ✔️ |

| Vinyl | ✔️ | ✔️ |

| Fiberglass | ✔️ | ✔️ |

| Metal Foil | ✔️ | ✔️ |

You should note that this table represents general adhesion properties, but the specific adhesion performance may vary depending on factors such as surface preparation, foam formulation, and application techniques. It’s always recommended to consult the manufacturer’s guidelines and perform adhesion tests on a small sample area before full-scale application.

Thermal and Air Sealing Capabilities

After discussing the expansion and adhesion properties of spray foam insulation, it’s important to delve into its thermal and air sealing capabilities. These qualities play a crucial role in maximizing energy efficiency, moisture control, and health benefits for homeowners and occupants.

Spray foam insulation’s primary function is to provide an effective barrier against heat transfer by offering high R-values per inch – a measure of thermal resistance. By filling every nook and cranny in walls, ceilings, and floors with this tightly packed material, you can dramatically reduce heat loss or gain through conduction.

Additionally, spray foam creates an exceptional air seal that prevents drafts from entering or escaping your home. This ability to eliminate air leaks can significantly lower heating and cooling costs while maintaining comfortable indoor temperatures all year round.

Moreover, proper moisture control within the insulated space helps prevent mold growth – directly contributing to healthier living conditions for those residing inside the property. So not only does this versatile product contribute to energy efficiency but also promotes a safer environment for inhabitants.

Phyiscal Properties: Texture, Color, Density, etc…

You’ll find that spray foam insulation has a unique texture, often resembling whipped cream, and can vary in color from light yellow to dark brown depending on the type and brand. Its density also differs based on whether it’s open-cell or closed-cell foam, affecting its insulating capabilities and overall performance.

The texture of the foam is essential as it determines how well it adheres to surfaces and fills cavities. Color variations can be useful in identifying different types of spray foams or simply for aesthetic purposes when applied in visible areas. Density factors play a significant role in determining the R-value (thermal resistance) of the insulation material.

Here are some key points to consider about the physical properties of spray foam insulation:

- Foam texture:

- Open-cell foam: Softer, spongier, and more flexible

- Closed-cell foam: More rigid and higher strength

- Color variations:

- Light-yellow hues typically indicate lower-density open-cell foams

- Darker browns are more common with higher-density closed-cell foams

- Density factors:

- Open-cell foam: Lower density (about 0.5 lbs./cubic ft.), lower R-value per inch (roughly R-3.5)

- Closed-cell foam: Higher density (around 2 lbs./cubic ft.), higher R-value per inch (approximately R-6)

Understanding these physical properties will help you choose the right type of spray foam insulation for your project while keeping in mind your desire to serve others by creating comfortable, energy-efficient spaces. It’s essential to consider not only how effective the insulation will be at conserving energy but also how its texture, color, and density might impact installation or aesthetics within a space when making your decision.

Polyurethane-Based Formulation

Now that we have discussed the physical properties of spray foam insulation, let’s dive deeper into its composition. Specifically, we’ll focus on the polyurethane-based formulation, which is one of the most common types used in residential and commercial applications. This type of insulation offers numerous benefits due to its unique characteristics and can be tailored to suit various needs.

One of the key aspects to consider when selecting a spray foam insulation is its eco-friendly benefits, health considerations, and versatility in usage. To give you an idea of how these factors come into play with polyurethane-based formulations, here’s a table summarizing some important information:

| Eco-Friendly Benefits | Health Considerations | Versatility in Usage |

|---|---|---|

| Energy-efficient as it reduces air leakage and lowers energy bills | Low VOC (Volatile Organic Compound) options available that minimize indoor air pollution | Can be applied to various surfaces such as walls, ceilings, floors or even irregularly shaped areas |

| Helps reduce carbon footprint due to decreased energy consumption | Closed-cell formulations provide added resistance against mold growth and moisture intrusion | Available in different densities (open-cell or closed-cell) for customized thermal resistance and structural support |

| Some options use renewable resources or recycled materials for a greener choice | Proper installation by professionals ensures minimal risk during application process | Suitable for both new construction projects and retrofitting existing structures |

As you can see from the table above, polyurethane-based spray foam insulation offers multiple eco-friendly benefits like reducing overall energy consumption through improved thermal performance. Moreover, there are health-conscious alternatives available that emit fewer VOCs while providing excellent protection against moisture-related issues such as mold growth. Finally, this type of insulation proves highly versatile in terms of usage – making it suitable for a wide range of applications across residential and commercial sectors.

Expansion and Rigid Structure

When spray foam insulation is applied, it undergoes a chemical reaction known as polymerization. This reaction occurs between the polyols and isocyanates present in the foam components. During polymerization, the liquid mixture transforms into a solid foam with a cellular structure.

The expansion of spray foam happens due to the release of gases generated during the polymerization process. Blowing agents, either chemical or physical, are incorporated into the foam formulation to create these gas bubbles. As the foam is sprayed onto the desired surface, the blowing agents decompose or vaporize, causing the foam to rapidly expand.

The expanding foam fills gaps, cracks, and voids, effectively sealing the area and providing insulation. It adheres to the surrounding surfaces, creating a continuous and seamless layer of insulation. The expansion process allows the foam to conform to irregular shapes and cavities, ensuring thorough coverage and maximum insulation performance.

Once the foam expands, it gradually undergoes a curing process. The curing involves the formation of cross-links between the polymer chains present in the foam. These cross-links create a rigid structure, providing stability and strength to the foam insulation.

The resulting rigid structure of spray foam insulation offers several advantages. It enhances the mechanical properties of the foam, making it resistant to deformation and capable of providing structural support. The rigid structure also contributes to the foam’s ability to act as an air barrier, minimizing air leakage and improving energy efficiency.

Chemical reactions during expansion and curing process

This curing period helps establish a durable and rigid structure within the foam by promoting further cross-linking between polymer chains.

However, one must be cautious when dealing with uncured polyurethane foam as it can release harmful gases like diisocyanates during this stage – proper ventilation and protective equipment are necessary measures for those working with these materials during this stage.

Mixing and Application

You’ll find that proper mixing and application techniques are crucial for achieving the best results with polyurethane-based materials. In fact, studies show that improper mixing can lead to a 50% reduction in insulation performance – emphasizing the importance of following correct procedures and guidelines.

Mixing techniques for spray foam insulation typically involve combining two separate components – an isocyanate (A) and a resin (B) – which react together to create the expanding foam. It’s essential to mix these two components at precise ratios using specialized equipment, as variations in ratio or temperature can significantly impact the quality of the final product. To ensure consistency and accuracy during this process, many professionals rely on advanced proportioning machines that automatically mix and heat the components at specific temperatures. To give you an idea of the stringent ratios refer to this graph below!

When it comes to applying spray foam insulation, choosing the right application equipment is key for both efficiency and safety. High-pressure plural component spray rigs are commonly used due to their ability to deliver consistent material flow rates while maintaining optimal pressure levels throughout the process. These systems provide excellent control over variables such as spray pattern size, allowing technicians to fine-tune their work based on each specific project’s requirements.

Additionally, safety precautions must be taken seriously when working with spray foam insulation materials; this includes wearing personal protective equipment like goggles, gloves, respirators, and full-body suits designed specifically for handling hazardous chemicals. By adhering closely to recommended guidelines and investing in high-quality application tools, you can contribute greatly towards ensuring successful installations while keeping yourself and those around you safe from potential risks associated with polyurethane-based products.

Flame Retardant Characteristics

Imagine the peace of mind you’d have knowing your home is protected with flame retardant characteristics built right into its walls. Spray foam insulation not only keeps your living space comfortable and energy-efficient, but it also offers significant flame resistance properties, enhancing overall fire safety.

This type of insulation undergoes specific treatments and additions of fire-resistant chemicals during manufacturing to achieve combustion prevention. As a result, spray foam insulation can slow down the spread of flames in case of a fire

One common flame retardant additive used in spray foam insulation is halogenated compounds, such as brominated flame retardants (BFRs). BFRs contain bromine atoms that act as reactive species during combustion. When exposed to heat, these compounds undergo a series of complex chemical reactions known as “flame inhibition” or “fire-extinguishing” mechanisms. BFRs can interrupt the combustion process by capturing free radicals and interrupting radical chain reactions, thus impeding the propagation of the flame.

Another type of flame retardant employed in spray foam insulation is phosphorus-based compounds. Phosphorus-containing additives release phosphorus radicals upon thermal decomposition. These radicals interfere with the combustion process by consuming oxygen and generating a protective layer on the material’s surface, limiting access to flammable gases and preventing further ignition.

Furthermore, intumescent flame retardants are often incorporated into spray foam formulations. Intumescent additives react to heat exposure by undergoing a complex chemical transformation. They swell and generate an expanded, foam-like char layer when exposed to high temperatures. This char layer acts as a thermal insulator and barrier, shielding the underlying foam from heat and flames, thus retarding the spread of fire.

Incorporating spray foam insulation in your building project demonstrates not only a commitment to energy efficiency but also an investment in fire safety measures that protect lives and property. So choose wisely: opt for materials that offer excellent thermal performance while ensuring peace-of-mind through their inherent flame resistance qualities.

Well… that was a lot, if you made it this far you earn a gold star. Sign up to our newsletter to redeem it.. until next time!